Grant, I use downcut bits in my lam trimer with this.

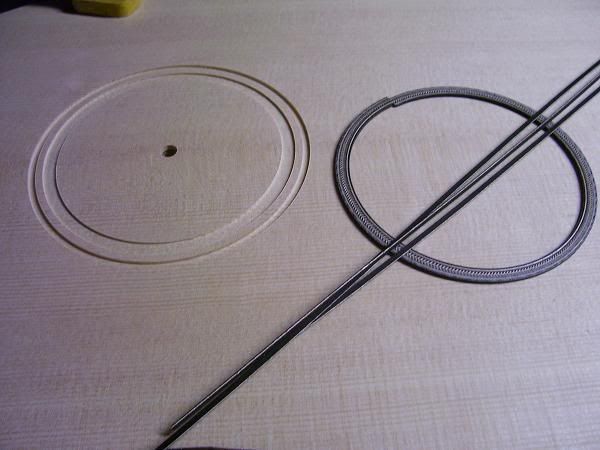

There has been lots of recent discussion on circle cutters. Mine is based off one that Tony Karol posted a while back.

Take a look here for several topics on circle cutters.

Sylvan Wells just posted a tutorial on how to build one of these things. It is very easy, quick and offers micro adjustments. You can't go wrong. Cost for materials is under $10, just have to have a laminate trimmer, which is sounds like you have one. So you just need the bits.

There have also been some discussions recently on bits. Take a look here for a good idea of where to get them. Lots of options.